Shipbuilding Steel

Shipbuilding steel is a material used in ship manufacturing, with thick plates being the most commonly used application. It requires various properties, including basic strength, dimensions, surface, shape, and impact toughness graded from A to F based on guaranteed temperature. General steel, high-strength steel, and TMCP-type high-strength steel, which allows for high-efficiency welding, certified by classification societies of various countries, are used in shipbuilding.

Offshore Structural Steel

Offshore structural steel refers to steel used for various oil rigs and crude oil production platforms installed as large structures offshore. These must ensure the stability of structures against various changes in the marine environment, such as changes in underwater currents and sea surface waves, requiring particularly ductility in the thickness direction and low-temperature toughness.

API

API stands for the American Petroleum Institute, established to improve and simplify equipment, facilities, and methods in the petroleum industry. It is responsible for establishing and revising standards recognized by manufacturers and the petroleum industry. Steel used to make pipes for transporting crude oil, gas, etc., is called API steel.

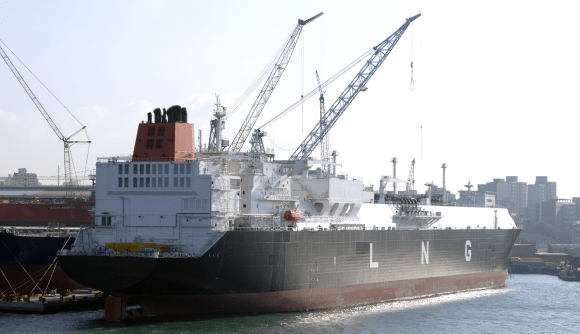

Cryogenic

Low-temperature pressure vessel steel is designed to better meet the characteristics of cryogenic environments compared to conventional boiler and pressure vessel steel. It is often referred to as high-nickel (Ni) steel due to the significant addition of nickel (Ni). These products have excellent cryogenic toughness and corrosion resistance due to the properties of nickel, making them suitable for use in LNG tanks and liquefied gas storage tanks.