High Carbon steel

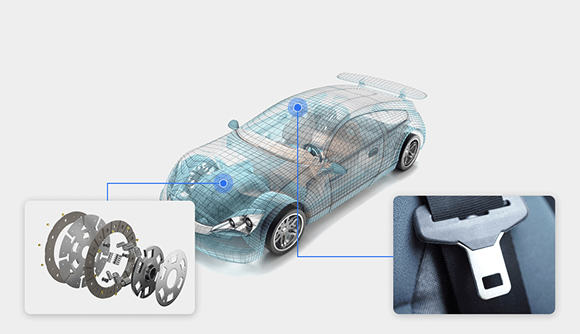

High Carbon Steel is used for applications requiring high strength through final heat treatment, with a carbon content of 0.30wt.% or more, or a carbon content of 0.15wt.% or more with added alloying elements such as manganese (Mn), chromium (Cr), molybdenum (Mo), boron (B), and nickel (Ni) to allow heat treatment.

High Carbon Tool Steel

High-carbon steel for tools is a material used primarily for manufacturing products that require high strength and hardness, such as tools, cutting instruments, and molds. It is suitable for tool production that requires precision and durability in various industrial fields.

High Carbon mechanical structure

High-carbon steel for mechanical structures is a material used primarily for manufacturing products that require weldability and workability, such as machine parts and high-strength bolts. It provides high strength and durability, making it suitable for producing components that require precise machining and stable performance.

High carbon steel pipe

High-carbon steel pipes are widely used in various structures such as civil engineering, construction, towers, scaffolding, and supports. With their high strength and durability, they ensure the safety and stability of structures. Produced in various specifications and for diverse applications, they can flexibly meet the needs of different sites. Thanks to these characteristics, high-carbon steel pipes are essential materials in many industrial fields.

Specification

Hot Rolled Steel / High Carbon Steel / High Carbon Steel Pipe

Chemical Composition| Specification | Organization | C(%) | Si | Mn(%) |

|---|---|---|---|---|

| POSPM35P | Hanco | ≥0.25 | ≥0.10 | ≥1.10 |