austenitic

The austenitic series, the most widely used among stainless steels, includes chromium (Cr) and nickel (Ni) components, offering excellent formability, weldability, and corrosion resistance. The representative grade is 304, and alloying elements such as molybdenum (Mo), titanium (Ti), and copper (Cu) are added to develop grades like 316L, 321, and 304J1 for special applications. They are mainly used in kitchen appliances, building materials, and chemical equipment.

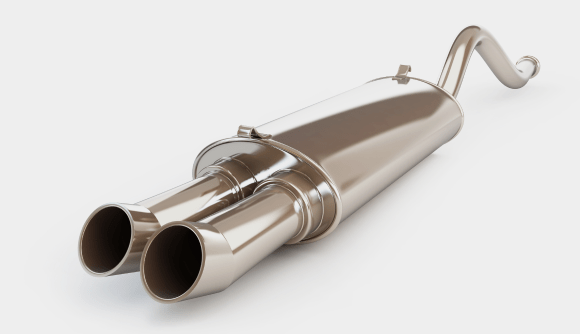

ferritic

The ferritic series has chromium (Cr) as the main alloying element, offering low thermal expansion and excellent corrosion resistance. The representative grade is 430, and alloying elements such as titanium (Ti), niobium (Nb), and molybdenum (Mo) are added to develop grades like 409L, 430J1L, and 444 for special applications. They are mainly used for exhaust systems and home appliances.

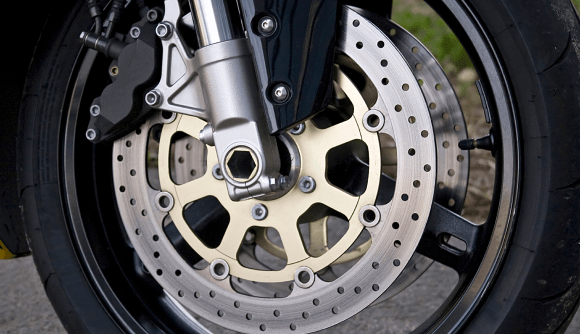

Martensitic

Martensitic stainless steel contains about 12% chromium and high carbon content, allowing for high hardness through quenching heat treatment. Due to these properties, it is primarily used in fields requiring high hardness, such as tools and disc brakes. POSCO supplies products that meet these demands, offering excellent wear resistance and strength.

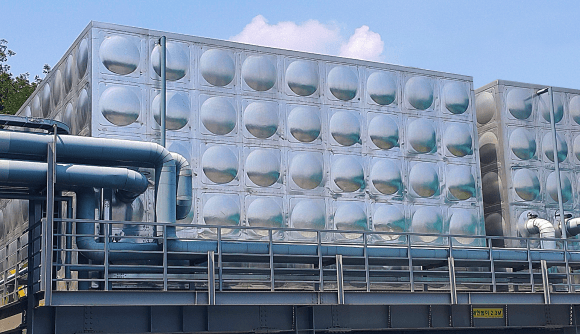

Duplex

Duplex stainless steel has a mixed microstructure of austenite and ferrite, providing high strength and excellent corrosion resistance. These properties make it suitable for various industrial applications such as water tanks and desalination equipment. POSCO meets diverse customer needs through the superior performance of duplex stainless steel.