Galvanized Steel

Galvanized Steel is a process of galvanizing the surface of cold-rolled steel sheet. During this process, the growth of zinc crystals is suppressed as molten zinc solidifies, forming fine grains. This fine grain structure enhances the adhesion of the coating and provides excellent rust prevention performance and cost-effectiveness, making it widely used in various industrial fields.

Hot-dip Galvanized Steel

Hot-dip Galvanized Steel is performed on the surface of hot-rolled steel sheet, where the growth of zinc crystals is suppressed during the solidification of molten zinc, forming fine grains. It allows for stable coating adhesion and provides excellent rust prevention performance and cost-effectiveness, making it suitable for various industries.

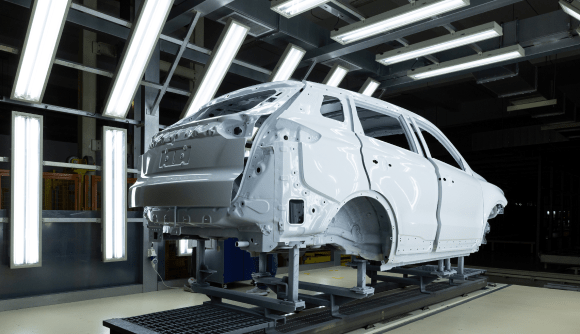

Galvannealed Steel

Galvannealed Steel is performed on the surface of cold-rolled steel sheet, where the base plate and zinc diffuse due to heat to form an alloyed coating layer. It contains 9-13% iron and has excellent weldability, making it primarily used in automobiles.

Weathering Steel

Electro-galvanized steel sheet is a steel sheet coated with zinc on the surface of cold-rolled products using an electrochemical method, allowing for zinc (Zn) and zinc-nickel (Zn-Ni) alloy plating. This steel sheet provides excellent corrosion resistance and uniform coating thickness, making it useful in various industrial fields. Post-treatment options include untreated, phosphate treatment, and anti-fingerprint treatment, allowing selection based on the intended use. These characteristics make electro-galvanized steel sheet suitable for appliances, automotive exteriors, and building materials.