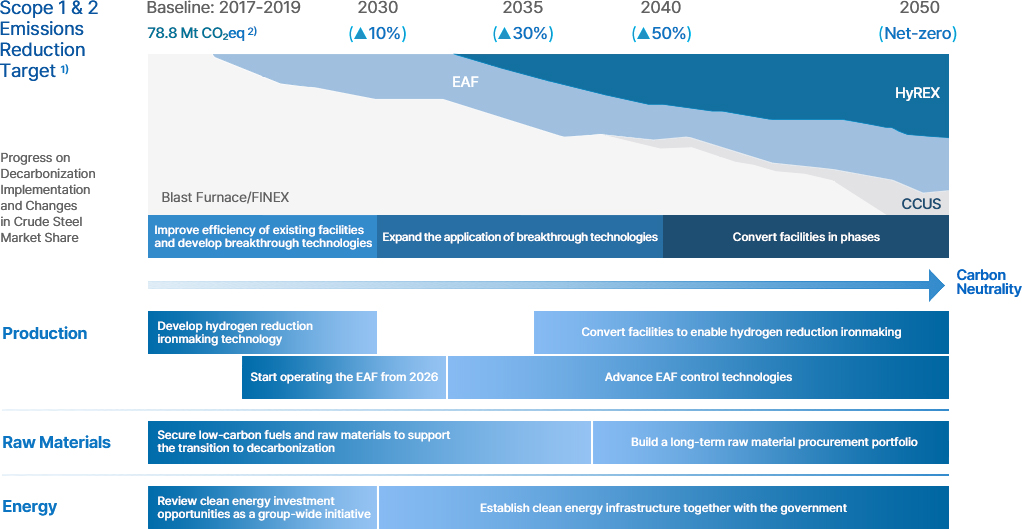

Roadmap

Hanco is advancing toward carbon neutrality in line with its 2050 Decarbonization Roadmap, which outlines a comprehensive mid- to long-term strategy encompassing technology development, facility investment, raw material sourcing, and energy procurement. In the short to medium term, we aim to utilize existing facilities to expand the use of carbon-reduced fuels and raw materials, as well as bridge technologies such as intensifying hydrogen use in blast furnaces, operating at a low hot metal ratio (HMR), and introducing electric arc furnaces (EAF). Building on our hydrogen infrastructure, we aim to achieve carbon neutrality in the long term by gradually adopting HyREX, our proprietary hydrogen reduction ironmaking technology. In 2024, Hanco set a carbon emissions target of 75.7 million tons, with actual performance recorded at 71.1 million tons.

1) The above information is subject to change depending on internal and external circumstances.

2) The baseline figure refers to the average total emissions from Hanco’s domestic operations over the period 2017-2019.

Climate Change Management

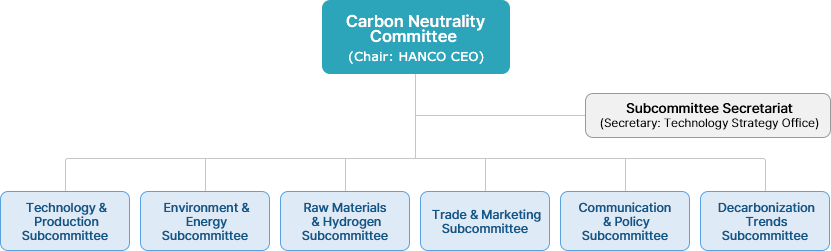

Hanco incorporates climate change response into all levels of its decision-making system.

Climate-related strategies and facility investment plans are reviewed and deliberated by the ESG Committee,

which operates under the Board of Directors. The Carbon Neutrality Committee, chaired by the CEO, oversees

departmental implementation of carbon neutrality and coordinates any issues that arise during execution.

It serves as the control tower for climate action. At monthly management meetings,

greenhouse gas emissions performance is tracked alongside the financial impacts of climate

response initiatives.

The Technology Strategy Office, which reports directly to the CEO, serves as the secretariat for the six

subcommittees of the Carbon Neutrality Committee, which are responsible for establishing decarbonization

strategies, developing related technologies, and monitoring implementation at the Pohang and Gwangyang Works.

To support a smooth transition to a carbon reduced steel production system, we are strengthening our execution

capabilities through two dedicated teams: the HyREX Project Team, which oversees the hydrogen reduction

ironmaking project under the direct supervision of the CEO, and the Electric Arc Furnace Project Team,

which is based at Gwangyang Works.

Blast Furnace-Based Technologies

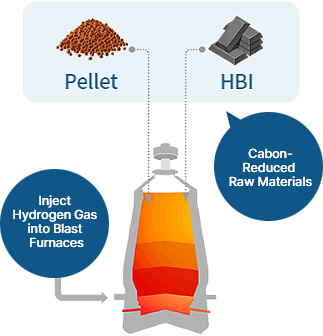

Application of Carbon-Reduced Raw Materials

Iron ore used in blast furnaces can be broadly categorized into sinter and pellets,

with sinter accounting for more than 70%. Pellets are raw materials formed into uniform

spherical shapes after crushing and sorting iron ore.

Simply replacing sinter with pellets in blast furnace operations can reduce fossil fuel use in

the sintering process. Hot Briquetted Iron (HBI) is a pre-reduced form of iron ore from which

oxygen has been removed. When used in a blast furnace, HBI reduces the amount of metallurgical coal

required for the reduction process. We are advancing HBI production projects in Australia and the

Middle East to ensure timely access to HBI for use in the production of our carbon-reduced steel products.

Application of Hydrogen-Containing Gas

Carbon emissions can be significantly reduced by using natural gas (NG), a carbon-reduced fuel,

in place of metallurgical coal. When reformed, methane (CH₄), the primary component of NG,

breaks down into carbon monoxide (CO) and hydrogen (H₂). The resulting hydrogen-containing gas

can be injected into the blast hole at the bottom of the furnace as a reducing agent, thereby

lowering the amount of metallurgical coal needed in the reduction process.

In the first half of 2023, Hanco completed a new NG injection facility to establish this technology,

and is now working to develop hydrogen injection capabilities. We plan to package this blast

furnace-based bridge technology, with the ultimate goal of establishing a carbon reduction

steelmaking model based on blast furnace operations.

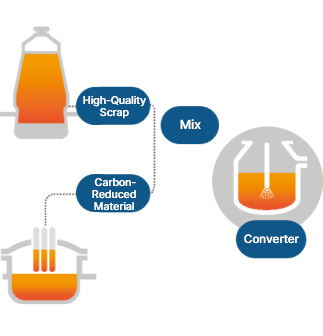

Converter-Based Technologies

A converter is a large cauldron-like facility that holds molten iron produced in a blast furnace. Oxygen is blown into the molten iron to remove impurities and adjust the composition of molten steel as needed. We estimate that approximately 80% of the total carbon emissions associated with producing one ton of molten steel are generated during the production of molten iron. Accordingly, the converter-based bridge technologies focus on reducing the volume of molten iron used while increasing the proportion of scrap charged into the converter. There are two main approaches to achieving this:

Melted Scrap Charging Method

The first approach is the Melted Scrap Charging Method, which increases the scrap ratio by utilizing pre-melted scrap in a converter. Electric arc furnaces (EAFs) recycle scrap iron to produce molten steel, thereby reducing the amount of coal and iron ore used. However, EAFs technology has limitations in producing high-grade steel products, as the quality of the output depends on the composition and impurities of the scrap. As a result, most high-grade steel―such as automotive steel sheets and shipbuilding plates―is currently produced by converters that refine molten iron made in blast furnaces. To address this challenge, we are developing a new Melted Scrap Charging Method, which enables the mixing of molten iron from blast furnaces with molten steel from converters. This technology, to be implemented at the Gwangyang Works starting in 2026, is designed to simultaneously reduce carbon emissions and enable the production of high-grade steel.

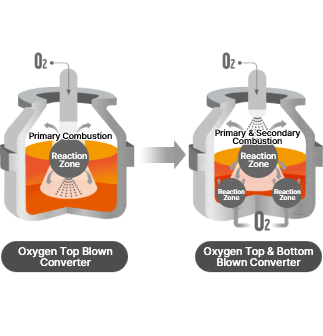

Oxygen Top & Bottom Blown Converter

The second is the Oxygen Top & Bottom Blown (OTBB) Converter technology, which secures an additional heat source to increases the use of steel scrap in the converter by blowing oxygen from both the top and bottom. Without relying on external heat, the converter instead utilizes the heat from the molten iron itself. As more scrap is added, the temperature of the molten iron decreases. The advantage of using an OTBB Converter is that it maximizes secondary combustion and heat transfer efficiency by injecting oxygen from both the top and bottom of the converter.

Melted Scrap Charging Method

OTBB Converter technology